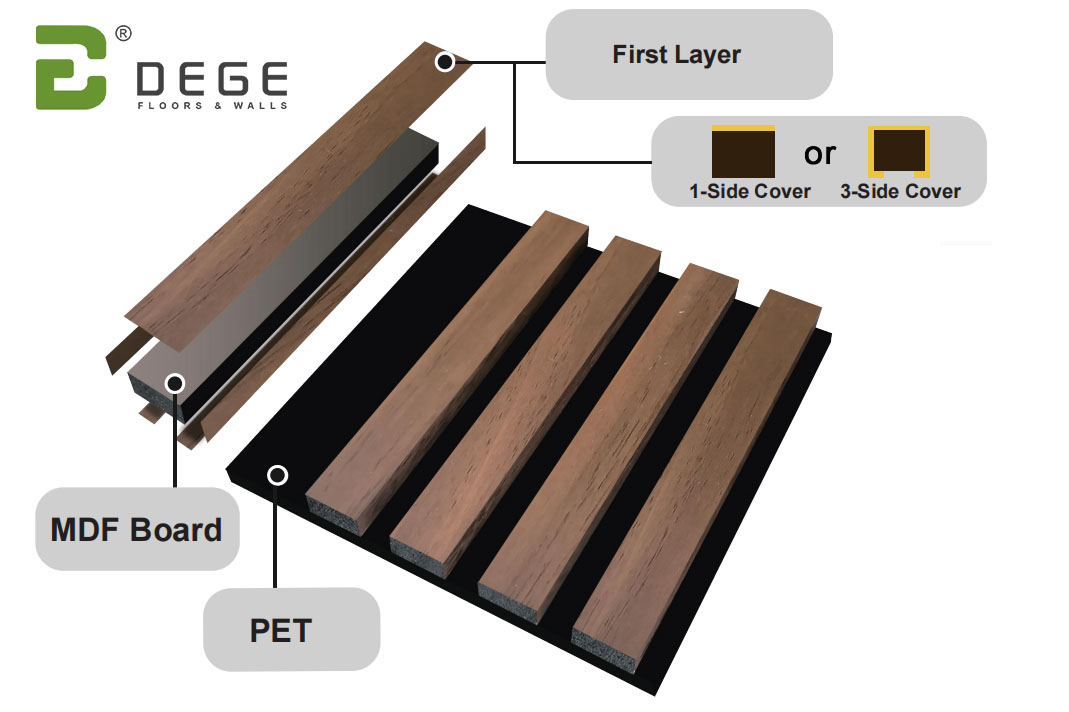

Structure of the Wooden Slat Acoustic Panel

The Wooden Slat Acoustic Panel consists of a Surface, MDF slats, and Polyester fiber panel. The production process is divided into six steps: Pressing – Cutting Slat – Stapling/Gluing – Edge Cutting – Shrink – Packing.

The surface has different materials: Melamine Paper, Technology Wood Veneer, Natural Wood Veneer, and PVC Film. The current method is divided into 1-sided cover and 3-sided cover. Technology wood veneer and natural wood veneer both can be made. Melamine paper and PVC film are generally choose 3-side cover.

MDF Slats Divided into different densities and different colors, but also have different thickness. The common density is 730-750 kg s / m3. Our commonly used thickness is 12mm.

Polyester fiber panel is a polyester fiber cotton as raw material, after special technology suppression production, and then processed into a plate. With good sound insulation, high environmental protection characteristics. There are different thickness, different density, different colors to distinguish. The common density is 1350G / M3 and 1700G / M3. The common thickness is 9mm.

Customers can choose different specifications according to their own requirements to meet different market needs.