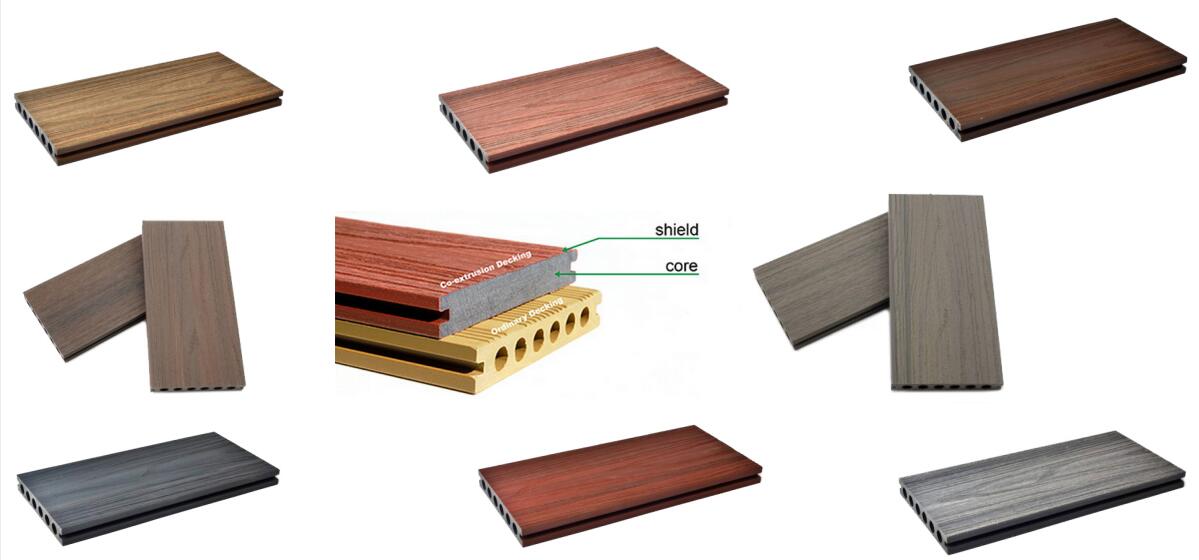

New Embossed Capped Composite Decking VS Ordinary WPC Decking

- Where are the charms of today’s Composite Decking? The answer is that it mimics the aesthetics of natural wood grain and richness standard wood deck boards provide. In order to meet the needs of the market and customers, WPC Decking is evolving step by step, from the initial grooves and different embossed to the current co-extrusion embossed.

Co-extrusion decking is the top high-end quality representative of WPC decking.

- What is co-extruded decking?

- Co-extrusion is made by mixing two or more material components through the same machine. Co-extruded technology is the most advanced technology currently being used in the composite decking industry. Compared with ordinary decking, co-extrusion decking has an extra layer of covering layer like a 360° protective cover.

- What are its advantages compared to ordinary decking?

- An extra layer of covering film means that the water absorption rate is 0%, and the waterproof effect is moreBy using the shield, co extrusion WPC Decking can better avoid problems like color fading, rot, crack,mold.

- Due to the special process, the surface is more like real wood grain

To imitate real wood, we launched the latest surface layer.

New 3D Embossed & Knife cut Embossed

- What is the difference between the pattern of the common co-extrusion decking?

- Repeatability - A repeating pattern of conventional decking 40cm on the market, ours is a repeat of 1.2m.

- Texture - The stripes are thicker and have a sense of solid wood, and the shape changes greatly.

- PE layer - Compared with the general co-extruded decking, the film on the surface is thicker.

- If you want to know more about our new products, please contact us.

- Email: sales02@dgfloors.cn