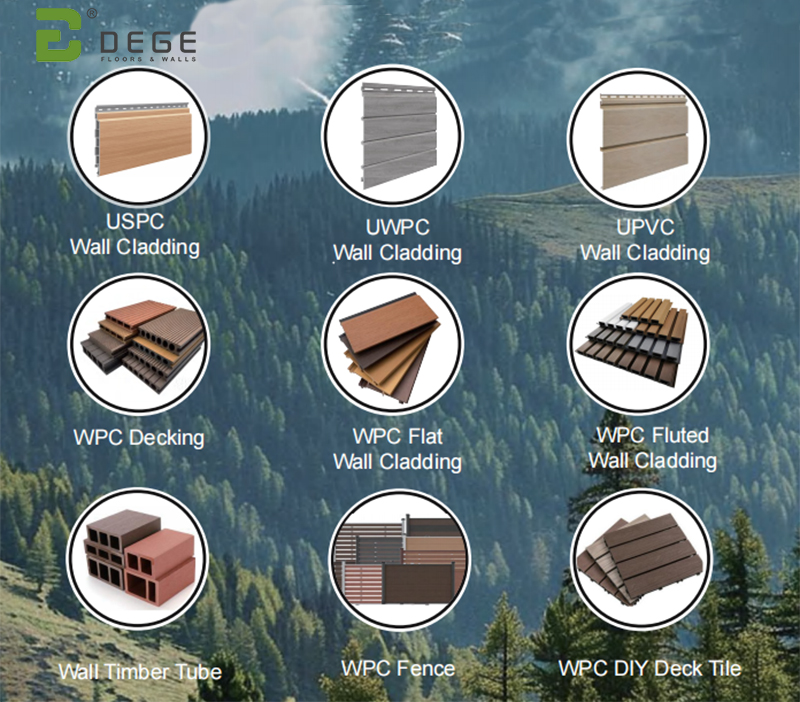

DEGE OUTDOOR PRODUCTS CLADDING AND DECKING

When referring to outdoor products, we can know outdoor decking, cladding, timber tub, fence and etc. We also have DIY flooring, the normal size of it is 300*300*20mm.

The producing process can be listed as follows, firstly, we need to use the granulation machine to produce the material of outdoor WPC products, and then, we can use the extrusion machine, next,we can put them into a model, to make what shapes we want. And then, the model of outdoor WPC products can be seen, next, we need to put the products in a place which we call this process as cooling treatment, and then we go to the process of health promotion, next the products will go to the sanding machine, now if you want to make some embossing surface on it, we can put it to the embossing machine, and until this time, the products are over, we can pack it and put into the carton and pallets.

For outdoor WPC PRODUCTS, we have co-extrusion and non co-extrusion, the difference is that the co-extrusion products have a PE film on the surface, after this treatment, the products can be more colorful and have a longer lifespan,so the co-extrusion decking is made up of two materials, using two machines at the same time. When referring to the end cap, non co-extrusion decking recommend 50*40mm and 41*41mm, the co-extrusion end cap recommend the 50*50mm.we have many colors for this , you can choose from our catalogs.