What is SPC Flooring?

Short for stone plastic composite, SPC is designed to identically replicate traditional flooring materials such as stone, ceramic, or wood, also provide many more practical benefits as you will see later in the article. Using realistic photographic prints along with a clear, vinyl top layer, SPC opens the door to a wide variety of design concepts. ![M[6]TVFYA)B_{HOXNVJK8QL](https://www.degeflooring.com/uploads/M6TVFYAB_HOXNVJK8QL.jpg)

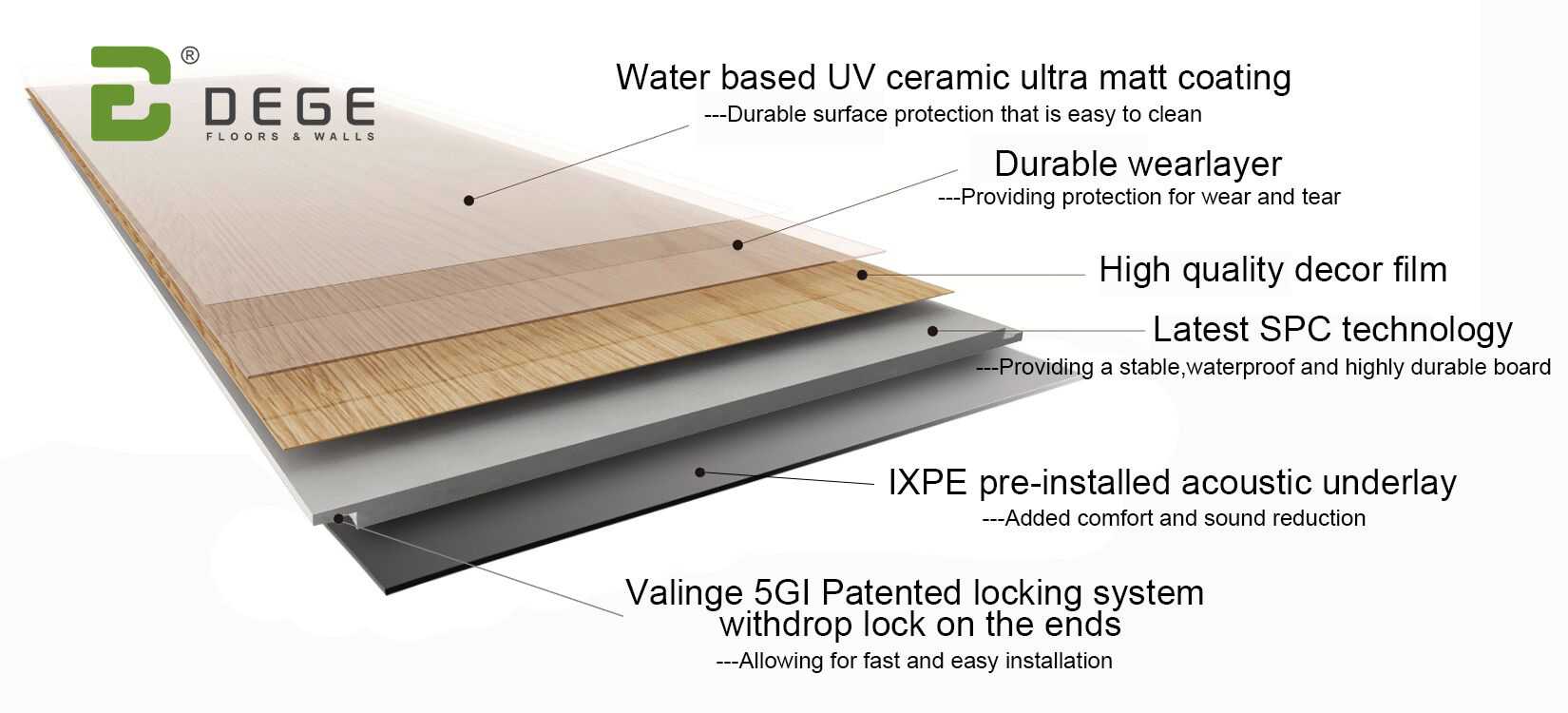

The structure of DEGE SPC flooring:

From top to bottom are UV layer, wear layer, color film and SPC core.

Besides, we will attach foam or cork(optional)to achieve sound dampening, resilient and moisture-proof performance.

SPC flooring is generally comprised of the five following layers in mind:

l UV Layer— A layer of UV paint,we call it a water based UV ceramic ultra matt coating, plus the UV layer,SPC flooring is easier to clean and more convenient to maintain. Generally, the lock SPC is added with UV.

l Wear Layer— Playing a crucial role in the lifespan of your tiles, this layer uses clear coatings such as aluminum oxide that will keep your floor from rapidly wearing.

l Color Film— Certain premium types of SPC come manufactured with realistic, 3D visuals that can be installed to identically resemble stone, ceramic, or wood.

l SPC Core — The core layer is where you get the most bang for your buck. Here, you will find a high density, yet stable waterproof center that provides rigidity and stability to the plank.

l Backing Layer — Otherwise known as the flooring’s backbone, this layer provides your planks with added sound installation, as well as being naturally resistant to mold and mildew.